MACHINES & CONSUMABLES

Coding & labelling

Solutions that improve uptime and traceability while reducing

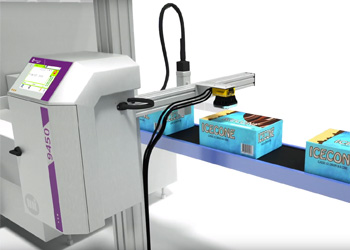

High-speed, high-throughput machines for permanent coding or labelling onto glass, plastic, cans, films, cardboard or PET bottles.

Markem-Imaje develop innovative inkjet, thermal transfer and laser systems, as well as label application and printing systems that will strengthen your digital supply chain with end-to-end individualised product traceability.

Best of all, the latest labelling and coding tech can code metal cans, glass and PET bottles. You can choose to use laser technology for cans and PET bottles, coding up to 120,000 units per hour, and eliminate the ink and additive in your factory.

Other option is to use quick-drying, high-adhesion ink — reducing batch labelling costs by up to 30%. And in the toughest and most variable production environments.

30% lower TCO. Full, secure traceability.

- Line uptime as high as 99%

- Eliminate bad print reprocess and waste

- Real-time print verification

- Eliminate non-conforming product

- Cut ink and fluid use

- Clean and green laser solutions

Inks and print methods to

Laser

Reduce your operating expenses with an ink-free operation that creates permanent, sharp codes on cans and plastic. These are ideal for anti-counterfeiting measures, and whenever you need to comply with financial and sustainability goals.

Continuous inkjet

Continuous inkjet printers can produce a two-line code on 120,000 containers or packs per hour with high visibility and contrast. Combined with a hygienic stainless-steel housing that can withstand regular washing, they’re ideal for the beverage industry.

Thermal inkjet

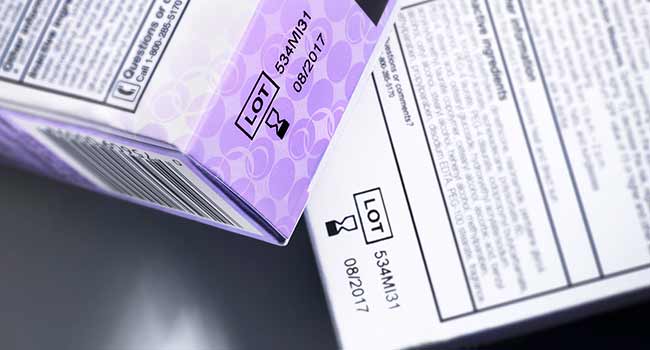

Tough, low-maintenance Thermal inkjet printers that produce high-resolution texts and logos, clear, readable barcodes and high-density graphics on secondary packages. Excellent for cardboard printing.

Thermal transfer printing

Designed to integrate easily into medium duty equipment, they offer high performance printing on flexible film packaging, while tracking data.