MACHINES & CONSUMABLES

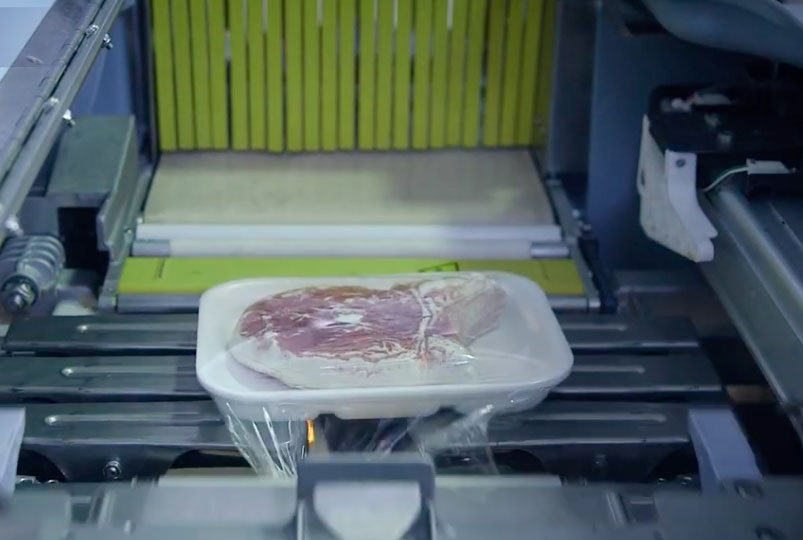

Packaging & sealing

Increase your efficiency with our packaging and sealing solutions.

Guaranteed savings through equipment that allows you to extend the useful life of food and protect and preserve the complete quality of the product, as well as state-of-the-art packaging machines and grouping systems that meet the highest safety, technology and economic requirements.

High product throughput, optimized consumable use and fast payback.

- Reduce labor cost

- Reduce shrink wrap and film offcut and waste

- Keep products pristine or fresh

- Improve quality and hygiene regulation compliance

- Raise product throughput

- Increase shelf life